Pultrusion molding process is a kind of automatic production process in which the reinforced materials such as glass fiber yarn and felt on the yarn frame are soaked by glue through continuous traction of the traction device, and solidified in the mold after heating the mold with fixed section shape, and the continuous mold production is realized. This type of curing is often referred to as high temperature curing.

Reinforced materials (glass fiber yarn, continuous glass fiber mat and the glass fiber surface mat, etc.) under the action of the traction in the pultrusion equipment, after dipping glue tank fully soak glue solution, consists of a series of reasonable orientation, preforming template get a preliminary shape, finally into the heated metal mold, mold under the action of high temperature curing reaction, Thus can produce surface smooth, stable size, high strength FRP profile.

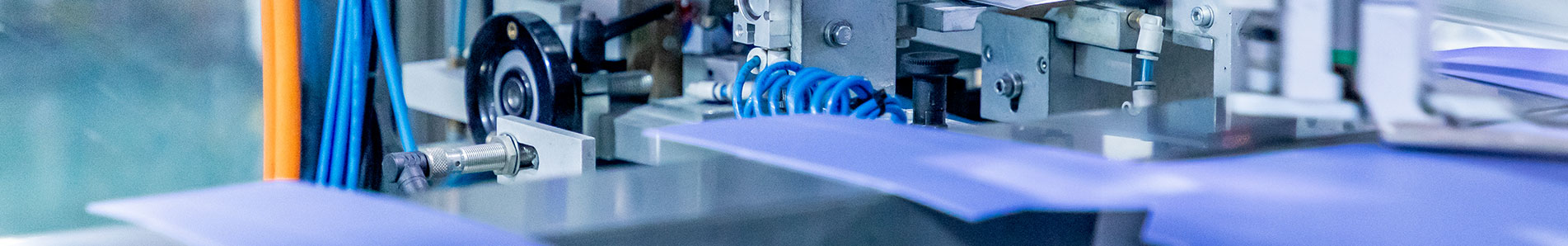

Pultrusion process equipment is mainly pultrusion machine, pultrusion machine structure is relatively simple, easy to operate, there is no special requirements for production workshop structure. Therefore, it is widely used in pultrusion industry. They are mainly composed of yarn feeding device, impregnation device, forming mold and curing device, traction device, cutting device and other five parts, their corresponding technological processes are yarn row, impregnation, mold and curing, traction, cutting.

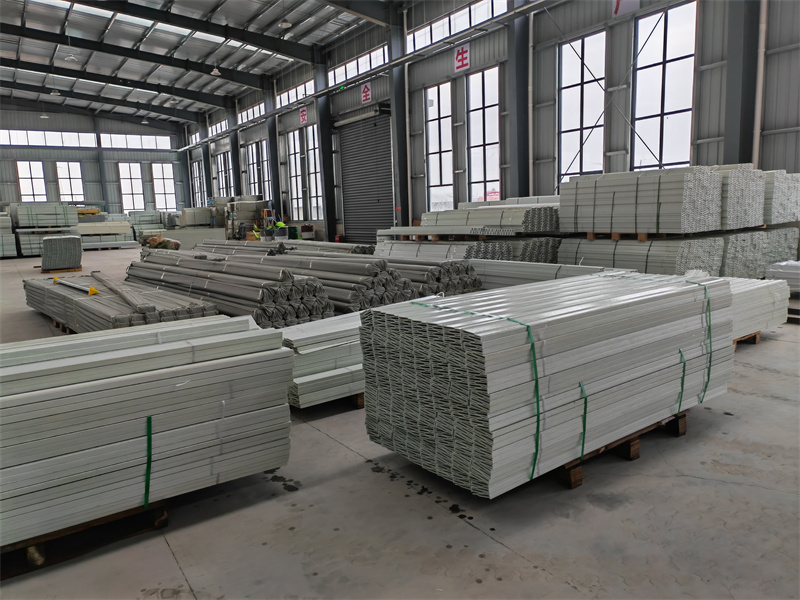

For FRP products with fixed section size, pultrusion technology has obvious advantages.

Firstly, because pultrusion is an automated continuous production process, the pultrusion process has the highest production efficiency compared with other FRP production processes.

Secondly, the raw material utilization rate of pultrusion products is also the highest, generally above 95%.

In addition, pultrusion products have low cost, excellent performance, stable quality and beautiful appearance. Due to these advantages of pultrusion process, its products can replace metal, plastic, wood and other materials, widely used in chemical industry, agriculture and animal husbandry, petroleum, construction, electric power, transportation, municipal engineering and other fields.

Post time: Sep-09-2022