FRP products refer to the finished products made of unsaturated resin and glass fiber. In fact, it is a new type of composite material products. FRP products have the advantages of light weight, high strength, corrosion resistance, good heating performance, strong designability and so on. FRP is widely used in construction industry, chemical industry, automobile and railway transportation industry, shipbuilding industry, electrical industry and communication engineering.

FRP material is also widely used in the shipbuilding industry, such as river passenger and cargo ships, fishing boats, hovercraft, all kinds of yachts, rowing boats, speedboats, lifeboats, traffic boats, FRP pontoons, mooring buoys and so on.

FRP material is also widely used in the shipbuilding industry, such as river passenger and cargo ships, fishing boats, hovercraft, all kinds of yachts, rowing boats, speedboats, lifeboats, traffic boats, FRP pontoons, mooring buoys and so on.

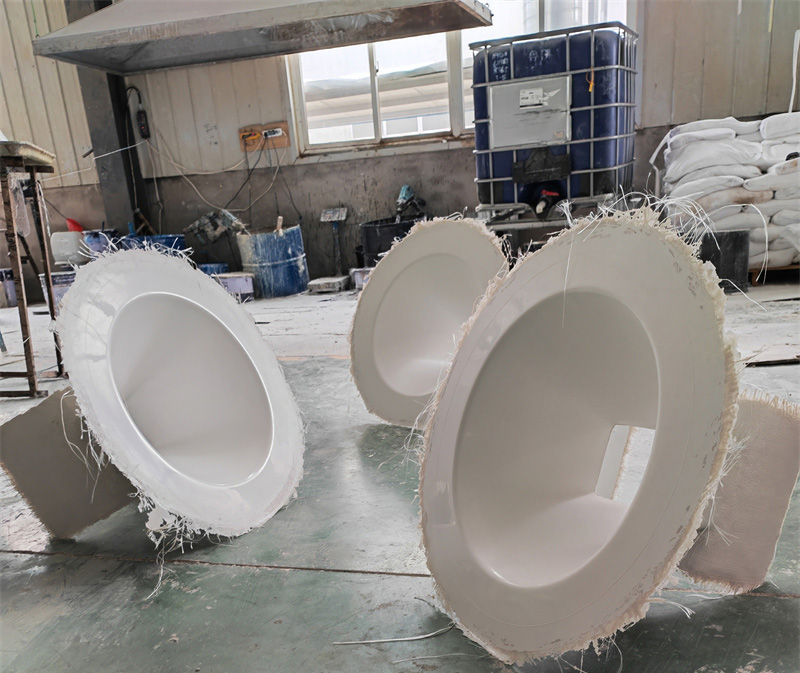

Hand paste molding process, also known as contact molding, is the earliest use of resin composite material production and application of the most common molding process. The process of hand paste molding is based on resin mixture with curing agent as matrix, glass fiber and its fabric as reinforcing material, and the two are bonded together by manual laying and coating on the mold to cure the molding by chemical reaction. Finally, the composite products were obtained by demoulding. This curing method is usually called room temperature curing.

In the hand paste molding process, the use of machinery and equipment is less, it is suitable for the production of special-shaped products, small batch products, and is not restricted by the type and shape of products. It is easy to meet the design requirements of products, and can be arbitrarily added or removed in different parts of products.

Hand paste product advantage

1. Mold cost is low, easy to maintain;

2. Production preparation time is short, easy to operate, easy to understand and learn;

3. Not limited by product size and shape;

4. According to the design requirements of the product, in different parts of arbitrary reinforcement, flexibility;

5. Curing at room temperature and forming under atmospheric pressure;

6. Color gelcoat layer can be added to obtain a rich and colorful smooth surface effect;

Item have passed by means of the national qualified certification and been well received in our main industry. Our expert engineering team will often be ready to serve you for consultation and feedback. We are able to also deliver you with cost-free samples to meet your specifications. Ideal efforts will probably be produced to provide you the most beneficial service and solutions. Should you be interested in our company and solutions, please make contact with us by sending us emails or call us straight away. To be able to know our solutions and enterprise. ar more, you'll be able to come to our factory to see it. We'll constantly welcome guests from all over the world to our firm. o build business enterprise. elations with us. Please feel absolutely free to speak to us for organization. nd we believe we will share the best trading practical experience with all our merchants.

Post time: Sep-09-2022